Urban Mining

Project description

please add

Commissioned services

please add

Client

please add

Order date

please add

Contact person

Dipl.-Ing. Hartmut Reichenbach

Managing Partner

Dr. Samereh Abdolali Pour, M.Sc.-Geol.

Sachverständige für Umwelttechnik

Environmental protection engineer Frederike Müller, M.Sc.

Expert pollutants in buildings

1. introduction:

In view of the increasing pressure on global ecosystems, sustainable and resource-conserving economic activity is the central issue of our time. An improvement can only be achieved if all sectors of an economy make constructive contributions through innovative concepts and solutions.

Current studies show that the construction industry has a considerable influence on the use of raw materials and the consumption of resources. In Germany, for example, around 90 percent of domestic mineral raw material extraction (517 million tons (mt) per year) is used in buildings or infrastructure projects. The share of recycled building materials in the total production of aggregates (584.6 million tons) was only 13.2% in 2020.

The construction material currently tied up in the German building stock alone is estimated at around 15 billion tons. In addition, there are around 11.5 billion tons in infrastructure buildings, of which around 90% is in roads (as of 2015). This is referred to as the anthropogenic stockpile (anthropogenic - man-made).

All in all, these materials have great potential as a future source of secondary raw materials. The process of collecting, classifying and using these materials in the course of dismantling is known as urban mining. Consumer goods such as electrical appliances and vehicles are also included as resources, but are not dealt with further in the following analysis.

The basis for the use of these materials as secondary raw materials is the sound exploration, analysis and evaluation of their condition and properties. Before dismantling or refurbishment begins, concepts for reuse or, if necessary, disposal must be drawn up on the basis of these investigations. In particular, the relevant official requirements and legal regulations must be observed. This is where S&P comes in with its consulting services.

2. the anthropogenic material store - central source for urban mining :

Various initiatives are currently attempting to record and map the material bound in infrastructure facilities and buildings. This is referred to as anthropogenic material storage. The mapping is carried out in so-called material registers. Based on data from 2010, the Federal Environment Agency estimates the total volume of anthropogenic material stocks in Germany at 28 billion tons, which can be recycled after use. Due to the importance of these resources, further studies have since been carried out.

Material storage Infrastructure structures:

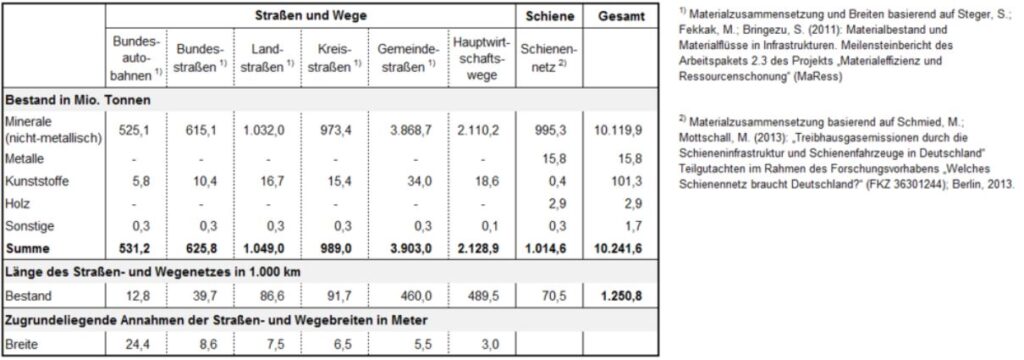

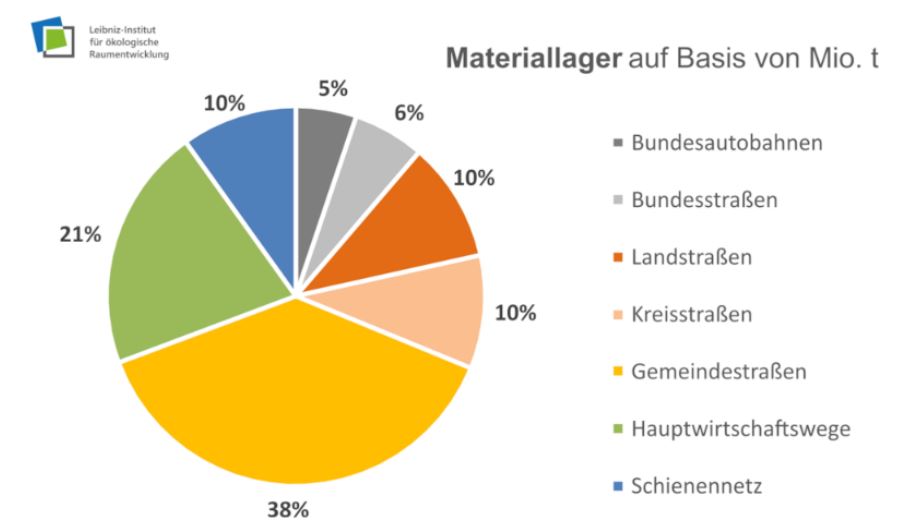

In their study commissioned by the Federal Environment Agency, Schiller et. al (2015) quantified the material stock of transport infrastructure (roads/paths/rails) at around 10.2 billion tons and allocated 99% to the mineral (non-metallic) fraction (Figure 1). Most of the material is bound in municipal roads at 38%, followed by farm tracks at 21% (Fig. 2). Bituminous binders in road construction and metals and impregnated wood in rail infrastructure account for only around 1%. The non-metallic mineral materials mainly comprise aggregates. These are gravels, sands and natural stones such as crushed stone, chippings, crushed sand and rock flour, as well as construction materials made from these, such as concrete.

Figure 1: Comparison of the material composition of infrastructure in the transport sector (Source: IOER)

It is clear to see that there is great potential for recycling here due to the high mineral content and the uniform structure of the traffic routes. Accordingly, extensive recycling regulations have already been issued in recent years and comprehensive monitoring has been introduced. The average recycling rate over the last 25 years is around 88.7%. It has been shown that a thorough examination of the material before and during dismantling is crucial in order to identify any contamination that may have occurred during operation, separate the material fractions concerned and thus enable targeted recycling.

Figure 2: Infrastructure transport material store (Source: IOER)

Material storage building

Compared to the infrastructure sector, the recording and mapping of materials bound in buildings is significantly more complex. This is due to the difficulty of accessing the inventory, e.g. in the case of private properties, the incomplete documentation of the materials used during construction or conversion and the lack of digital availability of this information.

Initiatives such as the Madaster Foundation, which was founded in the Netherlands to map existing buildings, promise an improvement here. However, the number of properties recorded is currently still comparatively low.

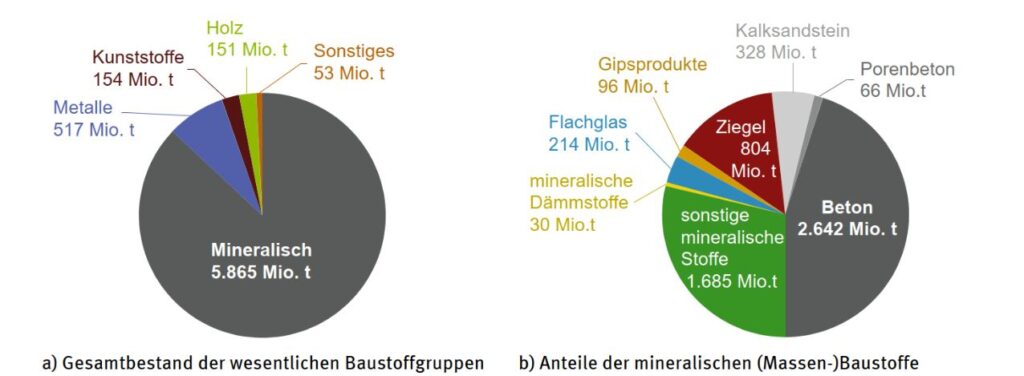

In their study published in 2015, Schiller et. al. examined all segments of the anthropogenic stock and, in addition to infrastructure, also carried out calculations for buildings. Here, a distinction was made between residential buildings, non-residential buildings and the building services installed in both building types. This shows that the share of building services is quite low at 1.3% of the total mass. The material stock in the building structure and interior fittings was determined using two different methods and is between 15 and 16 billion tons. The proportion of non-residential buildings is around 40%, mineral materials account for 90% (Fig. 3) and 95% for residential buildings.

Figure 3: Distribution of building materials in the non-residential building stock (Schiller et. al. 2015)

Due to the increasingly complex structure of buildings, e.g. to improve thermal insulation or soundproofing, the separation of materials, particularly in the area of interior fittings and façades, is becoming increasingly complex during dismantling, making it more difficult to return materials to the material cycle. Another problem lies in the past use of products containing asbestos or construction chemicals, which require separate and expensive disposal. It is therefore important to examine the materials in advance of any construction work in order to detect contamination at an early stage, separate the material fractions where possible and send them to suitable reuse or disposal channels.

The above-mentioned study found a significant increase in the anthropogenic stock of buildings during the period under review. The addition/demolition factor was 2.7, although there are certain mathematical uncertainties here. However, this tends to make it clear that the material requirements for new construction cannot currently be covered by the resources in the anthropogenic stockpile, even with a high recycling rate. Additional natural raw materials will therefore also be required in the foreseeable future. The Federal Environment Agency currently assumes that a reversal of this trend will not be possible until around 2050.

Overall, it can be stated that the anthropogenic material stock in Germany continues to grow and is constantly changing in its composition. Knowledge of the main existing materials and their environmental compatibility therefore forms an important basis for estimating material flows and potential for the circular economy in the construction sector. This is where S&P makes an important contribution in the field of building substance assessment consulting.

Material register

Material registers describe the anthropogenic material stock of buildings (residential and non-residential) and infrastructure structures (roads/bridges/locks etc.).

Material registers are created for cities, regions or real estate portfolios, for example, and provide important information on how these can be developed in a circular manner over the course of their life cycle. There are now also private-sector initiatives in this area, such as the Madaster platform developed by the Madaster Foundation in the Netherlands in 2017, which now records data from over 900 existing and 600 new-build properties in Germany. The online platform makes it easier for builders, planners, architects and other stakeholders to strive for and implement the circular use of products and materials in the construction industry. The platform can be used to store and manage data on materials, building materials and components used in buildings or infrastructure projects. The data can be enriched with further information and exchanged.

Based on planning data (BIM models, bills of quantities or component catalogs) or inventory records, it is possible to create a material passport or digital building resource passport. This material passport contains information on material masses, residual financial value, CO2 footprint and circularity. The material passport therefore also provides information about the quality, origin and location of materials contained in a building or construction. However, information is also collected on chemical ingredients, product compositions, recycled content or figures on the life cycle assessment or recyclability of building materials.

With the help of such documentation, it is possible to organize buildings and infrastructures as real commodity depots, to record and manage the additional residual commodity values of the properties and infrastructures and even to use them for accounting purposes or for the valuation of a property. S&P's building surveys and asset valuations form the basis of this documentation for existing properties and thus create recognizable added value for our clients.

Current situation of the circular economy in the construction sector

According to the 13th monitoring report of the Construction Circular Economy Initiative (2020), mineral construction waste, including excavated soil, is the most important waste group in Germany in terms of volume at 220.6 million tons (mt). 129.2 million tons (approx. 58%) of this was accounted for by the soil and stone fraction, which is made up of excavated soil, dredged material and track ballast, 85.7% of which was recycled - mostly directly for backfilling above-ground excavations or in landfill construction.

The remaining 91.4 million tons of construction waste consisted of building rubble, road demolition waste, construction site waste and gypsum-based construction waste. Most of this construction waste has high recycling rates of over 90 %. However, this also includes low-value recycling measures such as landfill construction or the backfilling of excavations. Only in the case of gypsum-based construction waste is a large proportion (over 40.4 %) disposed of in landfills. Compared to the 12th Monitoring Report “Mineral Construction Waste 2016”, the total amount of construction waste has increased by approx. 1.8 million tons. In contrast, the recycling rates have changed only slightly.

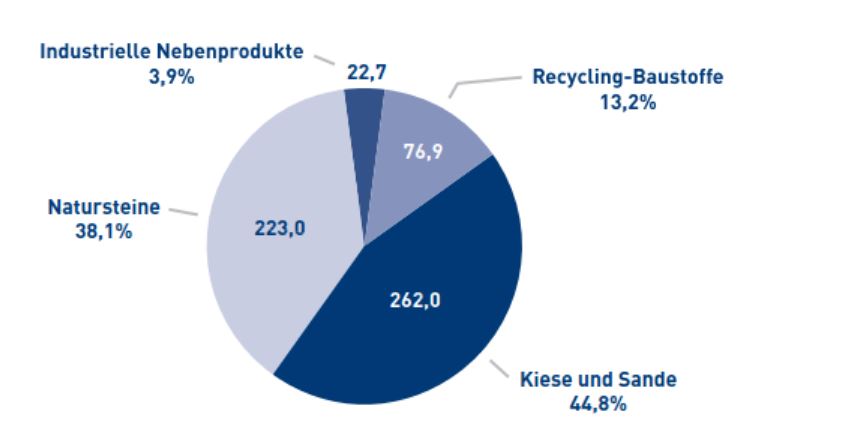

Ein besonderes Augenmerk bei der Wiederverwertung liegt auf der Gewinnung hochwertiger Recycling Baustoffe (RC-Baustoffe). Als RC-Baustoffe werden Gesteinskörnungen bezeichnet, die durch Aufbereitung mineralischer Bauabfälle hergestellt werden. Im Jahr 2020 betrug das Aufkommen mineralischer Abfälle der Fraktionen Bauschutt und Straßenaufbruch insgesamt 77,6 Mio.t. Daraus wurden 63 Mio. t Recyclingbaustoffe hergestellt. Die Recyclingquote betrug 82%. Insgesamt wurden 2020 rund 76,9 Mio. t Recyclingbaustoffe hergestellt. Damit deckten die Recycling-Baustoffe einen Anteil von 13,2 % des Bedarfs an Gesteinskörungen von 584,6 Mio. t (Bild 4).

Figure 4: Share of material fractions in the total volume of aggregates produced in 2020 (source: 13th Monitoring Report)

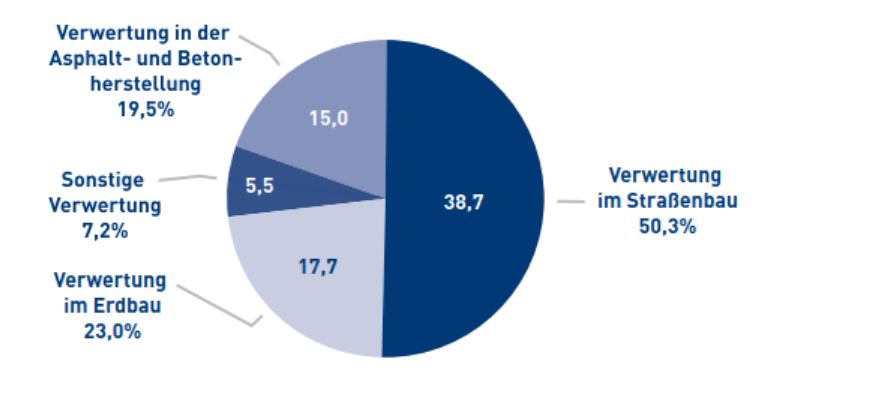

The majority of RC construction materials are currently used in road construction and, despite their defined and tested properties, are generally of low quality and used close to the ground, for example in landscaping and road construction or as a leveling material (Fig. 5). The use of recycled aggregates with defined technical properties in applications that do not place any special demands on the material corresponds to downcycling, which is due to informational, logistical and legal obstacles. In order to achieve decisive improvements here, increased efforts are required in the future. In particular, its use as an aggregate for concrete in building construction must be increased.

Figure 5: Recycling areas for recycled building materials in 2020 (source: 13th Monitoring Report)

The development of the aforementioned material registers will create more transparency in the material flows of anthropogenic material stocks in the future. This can support the transition to a functioning circular economy in the construction industry and facilitate the effective recycling and reuse of materials, building parts and other components. We actively support and advise our clients in material flow management with our waste management investigations of excavated materials and buildings and assessments during construction.

Circular planning and building

In the long term, the conservation of our natural resources can only succeed if renewable or recyclable materials and, above all, building products that are as durable as possible are specified and used right from the planning and construction stages. If possible, the materials used should be 100% recyclable.

In planning practice, the implementation of this vision is challenging and time-consuming. Digital tools and digital material databases can be used to select suitable materials for planning. The recyclability of a structure and the reusability of materials are decisive parameters for circular planning and construction.

In order to create transparency here, the relevant data on the building products offered and installed must also be comparable. This data can then be compiled into so-called building resource passports, which are offered by various organizations. For example, the DGNB's building resource passport documents all the materials and products used in detail, creating transparency and highlighting optimization potential to promote the circular economy in the construction industry. This makes it possible to plan buildings sustainably and economically and to minimize CO2 emissions. In the long term, this also increases the service life and profitability of properties.

The Building Resource Pass transparently presents the ecological and economic benefits of a property to owners, planners, companies and local authorities. This makes the passport an important tool for circularity, as it facilitates recycling and the single-origin processing of materials. It paves the way for the sensible use of resources from demolition and refurbishment and for buildings as a basis for urban mining. We actively support our customers in the geotechnical and civil engineering segments in the selection of materials and demonstrate economical and sustainable solutions.

Services from S&P

The basis for the use of these materials as secondary raw materials is the sound exploration, analysis and evaluation of their condition and properties. Before dismantling or refurbishment begins, concepts for reuse or, if necessary, disposal must be drawn up on the basis of these investigations. In particular, the relevant official requirements and legal regulations must be observed.

We advise our clients on all issues relating to the classification of soil material and building substance under waste legislation. With our waste law investigations, we create a reliable basis for your project in the early planning phase. If increased levels of pollutants are identified, we plan and supervise further detailed investigations and, based on the results of the analysis, identify cost-effective solutions. We are also happy to support you during the construction phase with excavation and material flow management with our waste management advice. Our experts will be happy to provide you with an initial assessment of your project situation.

Contact person:

Dipl.-Ing. Hartmut Reichenbach

Managing Partner

Dr. Samereh Abdolali Pour, M.Sc.-Geol.

Sachverständige für Umwelttechnik

Environmental protection engineer Frederike Müller, M.Sc.

Expert pollutants in buildings

Bibliography:

Georg Schiller, Sören Steger, Jan Reichenbach et.al. (2015), Texts 83/2015 in the publication series of the Federal Environment Agency, Dessau-Roßlau, October 2015, 315 pages

13. Monitoring Bericht der Initiative „Kreislaufwirtschaft Bau“ (2020), Herausgeber: Bundesverband Baustoffe-Steine und Erden e.V., Berlin, Januar 2023, 16 Seiten.

Webseite der Deutschen Gesellschaft für Nachhaltiges Bauen: https://www.dgnb.de

Website Leibnitz Institute of Ecological Urban and Regional Development, IOER, Dresden: https://www.iör.de

Website of the Madaster Foundation for Germany: https://madaster.de

Website nbau. Sustainable building: https://www.nbau.org

Website of the Federal Environment Agency: https://www.umweltbundesamt.de

Website of the Wuppertal Institute for Climate, Environment and Energy, Wuppertal: https://wupperinst.org